Aircraft maintenance is one of the most crucial parts of aviation. Without highly skilled and attentive mechanics, planes wouldn’t take off, let alone fly safely across the world.

In this exclusive interview, The Friendly Skies explores the daily routines, challenges, and rewards of life as an aircraft mechanic, through the personal experience of a technician currently maintaining Airbus A320 aircraft at Vilnius Airport in Lithuania.

Whether you’re considering a career in aviation maintenance or simply curious about the people who keep aircraft running safely and smoothly, this is a firsthand look at life on the ground, under the wing, and behind the cockpit door.

1. Why did you decide to become an aircraft mechanic? How long did it take, and what steps did you go through to become one?

I stumbled upon this job quite randomly, but I’ll probably remember how it happened for a long time. After graduating from college as an auto mechanic, I spent about six months job hunting—sending out my CV to various car repair shops without much success.

One winter day, I went to a workwear shop near the airport to buy some gear for a different specialty I had been studying. There, I unexpectedly ran into a former classmate from college. We had a quick chat about life after graduation, where he was working, and so on. That’s when I first heard about aviation maintenance. He asked if I was looking for a job and mentioned he could check if there was an opening for another mechanic. I said I’d think about it—and now, here I am, working as an aircraft mechanic for nearly a year and a half.

If it weren’t for my old friend from college, I probably wouldn’t know anything about aviation today. I’d likely be working in a more conventional job or still searching for one.

2. How long did it take before you were fully qualified to work on the A320 or any other aircraft?

From day one, I started learning about the Airbus A320—how to open and close doors, the correct working procedures, and even sat in a cockpit. Of course, I had to read manuals, pass various tests, and understand proper work practices.

Since our company handles both basic maintenance and various projects inside the cabin, my first 1–2 months were mostly spent inside the cabin. I also began performing basic maintenance tasks like checking tire pressure, brake condition, tire tread depth, and more.

3. Do you work mostly at Vilnius Airport, or do you travel to different locations for your job?

At the moment, I work only at Vilnius Airport (VNO), but there are always opportunities to travel abroad and gain new experience.

4. What does a typical day look like for you when working on an aircraft?

It depends on the season and whether any major projects are underway. Usually, we start the day with a team briefing to go over scheduled tasks. Then we’re divided into small groups and assigned specific jobs.

Before starting any task, we print and review the relevant manuals to understand both the procedure and potential hazards. After that, we gather the necessary tools and begin work.

5. What are some of the most important daily safety checks you perform?

The most common ones are daily and weekly checks. These often depend on customer requirements, but typically include:

- Tire tread depth and condition

- Tire pressure

- Brake system

- Crew oxygen pressure

- Door damper pressure

- Oil levels for the engine, APU, and IDG

- General visual inspections for abnormalities

6. What kind of tools or technology do you use when working on the A320 or other aircraft?

The tools are pretty similar to those used for cars or motorcycles, but with one major difference—they follow the imperial system, not metric.

7. Is there anything unique about the Airbus A320’s design (or any other aircraft you’ve worked on) that makes it easier or harder to maintain?

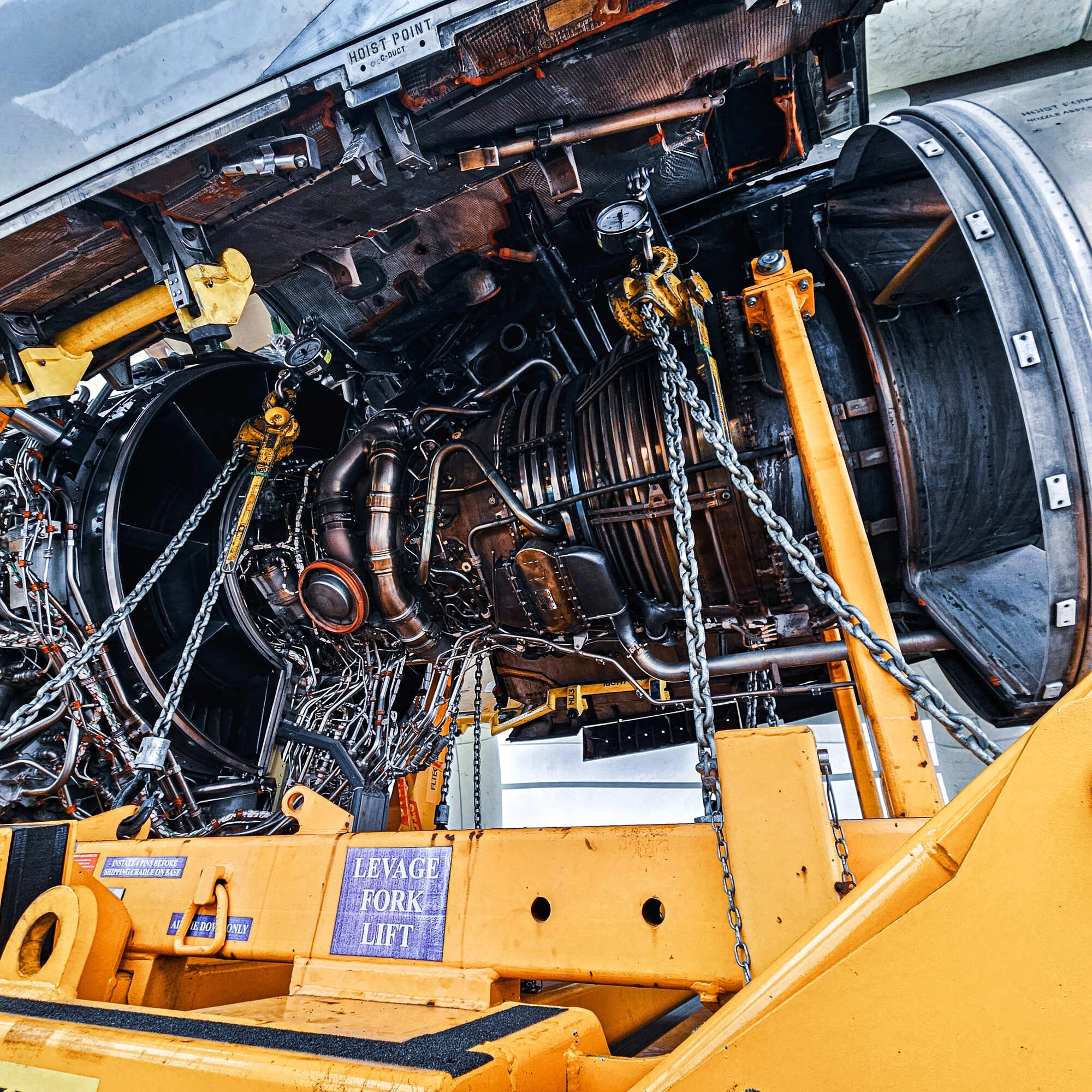

Since I mostly work on the A320, I don’t have much to compare it to. Overall, it’s fairly straightforward. Some tasks can be challenging, especially when there’s limited space—like trying to unscrew a bolt in a tight spot.

8. Have you ever found a problem that could’ve caused a serious issue if it wasn’t fixed? What happened?

So far, I haven’t encountered any major or life-threatening issues during my time in the field.

9. How often do you update your knowledge or training to keep up with new aircraft systems?

The aircraft I work on are fairly old, so updates are rare. However, I constantly try to learn more about various systems by observing and asking questions from more experienced colleagues.

10. Are there any downsides or frustrations about being an aircraft mechanic that people might not realize?

Yes, a couple. If you work in line maintenance, weather can be a big issue—wind, rain, or snow can delay or prevent work and increase the risk of getting sick. Another downside is the exposure to chemicals. There is always a chance that you can get something on your hands that could harm your skin so you always have to wear personal protective equipment (PPE).

11. Do you ever feel pressure knowing the safety of hundreds of passengers depends on your work?

Sometimes yes, sometimes no—it depends on the task. I always follow the manuals and try to do my best. Some tasks are double-checked by experienced engineers, which also helps ensure safety.

12. What’s one thing you think more people should know about aircraft maintenance?

It’s not as complicated as it looks—but you have to be ready to start learning again, from scratch.

13. What’s the most fun or satisfying part of your job?

Fixing problems and then watching the aircraft take off without any issues—that’s incredibly satisfying.

14. What’s the strangest or funniest thing you’ve ever found in an aircraft?

Random slippers.

15. Do you still enjoy flying as a passenger, or do you just think about what’s going on under the hood?

I don’t really enjoy flying—but I do love wrenching and fixing things.

16. If you could work on any aircraft in the world—past or present—which one would it be, and why?

I’d love to gain experience on Boeings or ATRs. I don’t have a specific favorite, but it would be amazing to achieve my dream by working on military jets like the F-16, Su-57, or even older aircraft with radial engines.

17. What’s the aviation industry like in Lithuania? Is it growing? Are there good opportunities for young people?

Yes, the aviation industry in Lithuania is slowly growing, although space for new hangars is very limited or even non-existent. As a result, companies often open stations in other countries.

If you like airplanes, know how to use tools, are responsible, aren’t afraid to get your hands dirty, and are interested in how various systems—like hydraulics and electronics—work, then I think this is a specialty worth choosing. However, to earn a good salary, you need to be prepared to spend a lot of time studying, taking exams, and gaining experience.

18. What do you think about the future of aviation? Electric planes, automation, fewer mechanics—what’s your take?

I’ve heard about a potential new license for electric aircraft and engines. Personally, I believe mechanical systems will always be more reliable than fully electric ones.

19. What advice would you give someone thinking about a career in aviation maintenance?

Be prepared to learn, read a lot, and get your hands dirty sometimes. Don‘t be afraid to ask questions, don‘t do things with your own understanding (don‘t be too confident in yourself, it‘s not always a good thing). Most importantly, if you love the job, everything will work out.

20. And finally—what’s your favorite airplane and why?

Definitely the Su-57 fighter jet. I love its sharp lines, angles, and overall design. It has an old-school, aggressive look that I really admire. I hope to see it in person one day.

A big thank you to the aircraft mechanic for sharing their story with The Friendly Skies.