Why are Airplane Windows Round or Oval?

When you are flying on an airplane and glancing out the window, you may overlook the fact that the window has a round or oval shape. This shape is not a simple or coincidental design choice, but plays a huge role in the safety and functionality of airplanes. Wondering why are airplane windows round? Let us explore the evolution of airplane windows and why having a round shape is important for these windows.

The Evolution of Airplane Windows

Early Aviation Days: Development of Square Plane Windows

Airplane windows have not always been round. In fact, windows were not part of early aviation history. When the Wright Brothers made the first sustained flight by their aircraft in 1903, they focused more on achieving powered flight rather than passenger comfort.

In the 1940s, developments in aviation allowed aircrafts to carry people at higher altitudes and longer distances. This was when engineers started refining many features in passenger cabins, including windows, for a practical and safe travel.

During this time, engineers chose to build square plane windows as they believed square windows would have a good structural integrity. However, history proved that square windows were unfavourable through a series of unfortunate tragedies.

The Risk of Square-shaped Airplane Windows

The Federal Aviation Administration (FAA) documented how square plane windows were a contributing factor to several accidents involving some planes in the early 1950s. Initially, the de Havilland Comet airplanes entered service in 1952, faster and more advanced than any planes built before it. However, the program later on faced disaster.

The first accident occurred in May 1953, when British Overseas Airways Corporation (BOAC) Flight 783 departed from Calcutta, India. After climbing to 7,500 feet, the plane broke up and crashed, killing everyone on board. The cause of the accident was determined to be structure failure from flying through a storm, or over-control of the aircraft by the pilot.

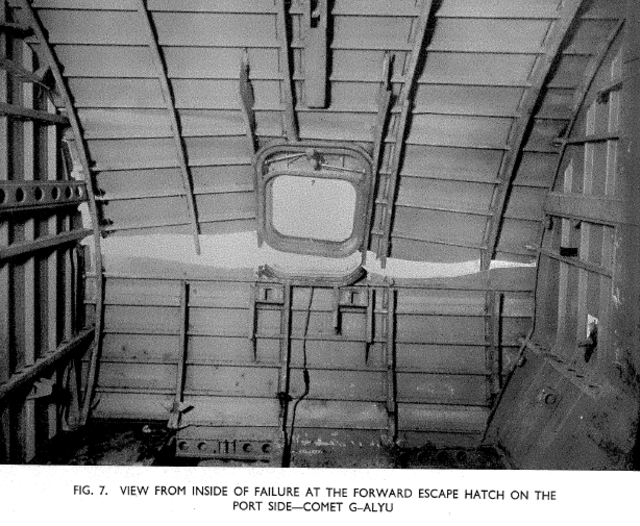

On 10 January 1954, BOAC Flight 781 was scheduled to depart from Rome to London. However, the jet suffered an explosive decompression at altitude and crashed near the Mediterranean Sea, killing all 35 people on board. The reason for the crash was determined to be explosive decompression from metal fatigue, originating from the corners of the square windows.

In April of the same year, South African Airways Flight 201 also crashed over the Mediterranean Sea, killing everyone on board. As a result, The Certificate of Airworthiness was withdrawn for all aircraft, grounding the fleet indefinitely.

Investigators concluded that all accidents were likely caused by the square windows. An aircraft is like a pressurized tube. During flight, the pressure inside the cabin is significantly higher than that in the outside atmosphere. Whenever the plane climbs and descends, the airplane body will flex slightly due to that pressure difference.

The presence of sharp corners on square plane windows may increase stress on the metal, leading to the formation of cracks. These cracks may spread and lead to structure failure. This proved how the window design in airplanes had to change, as curves are stronger than corners.

The Importance of Round Airplane Windows

Round or oval airplane windows marked a pivotal advancement in aviation safety. The lack of corners means there is nowhere for pressure to focus, eliminating any stress points. With an even pressure distribution, there is less risk of fatigue cracks. Nowadays, no matter what type of plane you board, you will notice that the windows are rounded. At the same time, round windows improve the window frame integrity, allowing multiple panes to be fitted for insulation, soundproofing, and strength.

Further Developments in Plane Windows

Over time, it is not just the shape of airplane windows that has changed to be more rounded. They are also constructed differently. For instance, most planes nowadays use acrylic instead of glass as the main material for windows for better durability. Acrylic is also more lightweight, leading to a decreased overall aircraft weight which improves fuel efficiency and performance.

Round airplane windows typically have three layers that work together for strength and safety. The outermost layer or outer pane is the thickest, and its function is to handle the brunt of external pressure exerted when the plane is flying. The second layer or middle pane helps to even out the outer and inner pressures. It has a small hole, called a breather or bleed hole, to even out pressure between the inner and outer section. Lastly, the thin, innermost layer is installed to withstand internal pressure of the aircraft, while serving as a protective barrier for passengers to prevent scratches or damage to the structural layers.

What Happens If an Airplane Window Breaks?

Airplane windows today are built with the safety and comfort of passengers in mind. However, you may still wonder, is it possible for an airplane window to break? What happens if an airplane window breaks?

In practice, airplane windows are highly unlikely to break due to their multiple layers. It requires a huge amount of force to break them. Each panel of the window is able to withstand pressure differentials of about 8 psi, the cabin-to-atmosphere difference at cruising altitude. Moreover, rigorous regular maintenance and inspections help prevent risk of window failure.

However, if an airplane window still ends up being broken, the first immediate event that follows is all the air in the plane would rush out. This is caused by differences in internal and external air pressures. The window breakage would create a type of suction effect, sucking objects out of it, followed by rapid fall of temperature and air pressure. In summary, what happens would be:

- Rapid cabin decompression as air flies away through the broken section

- Temperature plunge to –50 °C or lower

- Oxygen depletion which causes passengers to get unconscious in seconds

- Unsecured or loose items could be displaced toward the breach

- Risky forces near the hole can be dangerous, causing passenger injury or ejection

In the case of an airplane window breaking, the immediate response would be to descend. It means that these forces will likely take effect when the plane descends low enough to compensate for cabin pressure loss, which is usually around 8000 ft in the air.

Has Airplane Window Breakage Happened Before?

Although aircrafts are designed to reduce the risk of the plane windows breaking, there have been several cases where it has happened. The first was the British Airways Flight 5390, which was scheduled for a flight from Birmingham Airport in England to Málaga Airport in Spain on June 10, 1990. A poorly installed windscreen panel fell out, causing the flight captain to be sucked out of the plane, only held in by flight staff. He survived with a fractured arm, frostbite and some minor injuries.

Another example that happened decades later was the Southwest Airlines Flight 1380, a Boeing 737-7H4 flying from LaGuardia Airport, New York, to Dallas Love Field, Texas on April 17, 2018. One of its passenger windows broke due to an exploding engine, killing one passenger due to being partially sucked out of the plane.

Shortly after, on May 14, 2018, another plane had the same issue. Sichuan Airlines Flight 8633, bound from Chongqing Jiangbei International Airport to Lhasa Gonggar Airport, had to make an emergency landing due to its cockpit windshield blowing out at 32,000 feet. The first officer was sucked out of the aircraft, sustaining minor injuries. All 128 people on board survived.

The Future of Airplane Windows

Airplane windows continue to undergo innovations, shifting from simple acrylic installations to sophisticated displays that could redefine in-flight experience. For example, the optical German company Zeiss aims to equip commercial jets with touch-free holographic Multifunctional Smart Glass systems.

While typically focusing on spacecraft, Zeiss is eyeing to upgrade the existing window panels in planes, blending the real-world view with digital overlays and controls. The new technology was displayed in the 2025 Aircraft Interiors Expo in Hamburg, Germany back in April this year. According to Zeiss, using multifunctional smart glass windows also offer the added advantage of reducing the plane’s overall weight.

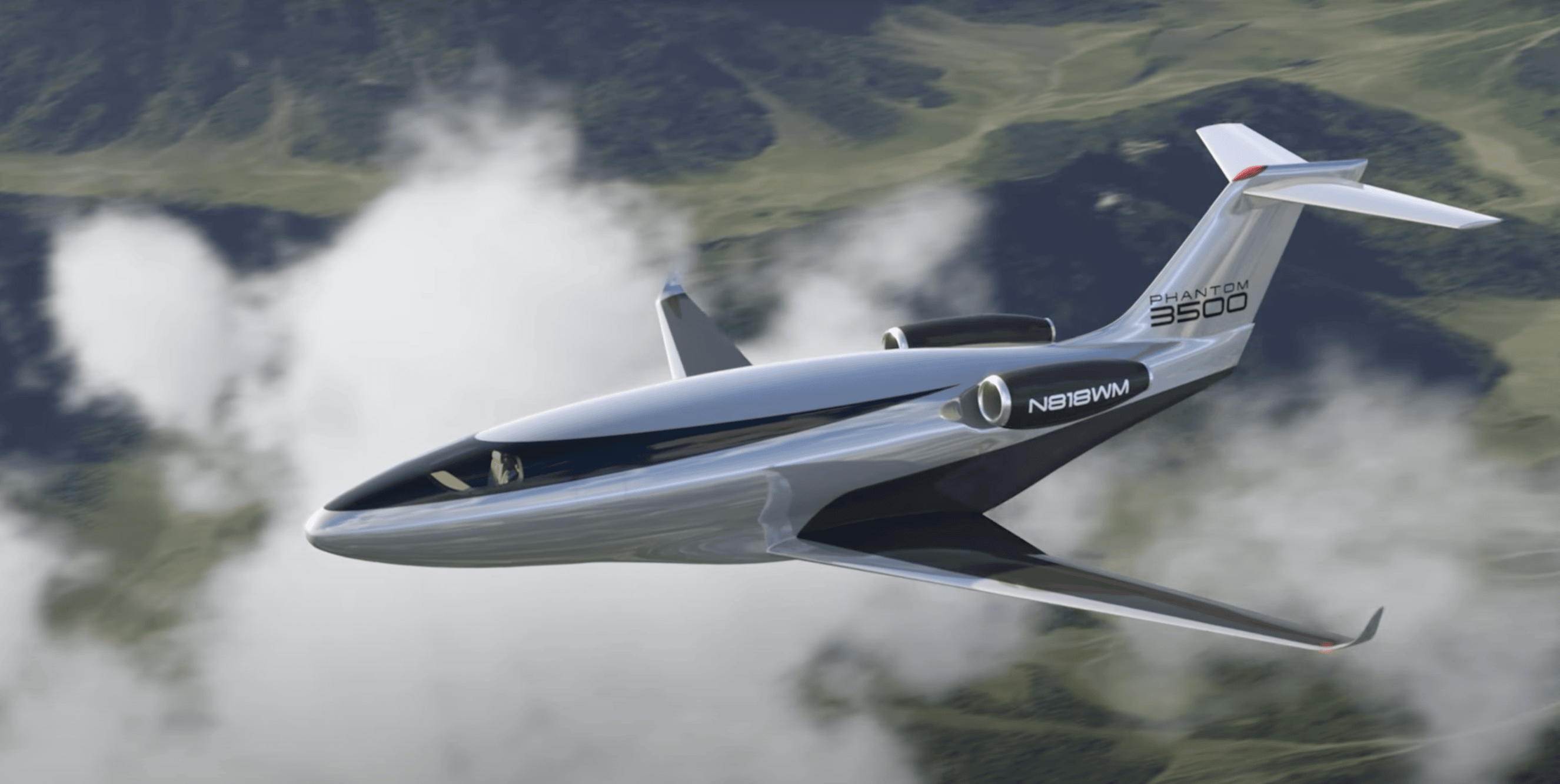

Otto Aerospace, a US aerospace company focusing on highly efficient private and business jets, also recently designed the Phantom 3500 jet. In addition to having a teardrop-shaped fuselage, it is windowless, except for the cockpit. The aircraft design is meant to reduce fuel consumption and increase range. Screens are fitted into the cabin sides where windows are usually placed, with ‘smart windows’ that show the exterior of the aircraft. Passengers can also switch them to watch TV or have virtual meetings.

While these unique innovations have yet to reach mainstream commercial flights, the classic round window design still remains a vital and non-negotiable safety feature on today’s airliners. However, these concepts chart an interesting course that we may see in the future of aviation design.

Final Thoughts

The evolution of airplane windows from square to rounded shapes represents a remarkable development in aviation history. Beyond an aesthetic choice, rounded airplane windows prioritize safety and functionality, implementing valuable lessons learned from past failures. Modern engineering also ensures that windows are able to withstand immense pressures and enhance passenger experience. As aviation technology constantly develops, keep an eye on how airplane windows will continue to evolve.